The What and How of Our Products |

|

What are the differences between sublimation and heat applied vinyl?

We work diligently to provide the best quality products possible. You work hard for your money and we work hard to provide the best quality at the best prices. We only use two processes of printing. Sublimation, and HTV (Heat Transfer Vinyl). While you can produce beautiful designs with both of these methods there are vast differences between them.

Sublimation

What is sublimation printing?

Sublimation is printing a vivid photo quality print using a printer, special ink and paper that is then heat transferred onto the substrate. For hard surfaces, the substrate must be a polyester coated surface. The polymer coated surface is specially designed to allow the dye to absorb into the fibers of the polyester. Once cooled the pores in the fiber seal locking the dye in place. The image is permanent and unless bleached, the colors stay vibrant much longer. They are essentially permanent. Our photo-gifts such as mugs,tumblers, etc are produced using this method.

We are pleased to announce that after many hours with our vendors, we have learned how to give you vibrant sublimated prints on 100% cotton fabrics. No longer do the colors have to be white or light colors, or ever polyester. The prints last much longer and are vibrantly beautiful. Our cotton sublimated prints are placed on a specially made ultra thin vinyl surface that allows the dye inks to seal into the vinyl. They are then heat applied to the garment. It is not layered.

When using sublimation to produce your product I only use the manufactures' recommended process. I do not use any hacks, short cuts or cheaper brands. I believe in doing so reduces the quality of the your product. My promise to you is to provide you with the best quality possible. I intended to do that every step of the way.

We work diligently to provide the best quality products possible. You work hard for your money and we work hard to provide the best quality at the best prices. We only use two processes of printing. Sublimation, and HTV (Heat Transfer Vinyl). While you can produce beautiful designs with both of these methods there are vast differences between them.

Sublimation

What is sublimation printing?

Sublimation is printing a vivid photo quality print using a printer, special ink and paper that is then heat transferred onto the substrate. For hard surfaces, the substrate must be a polyester coated surface. The polymer coated surface is specially designed to allow the dye to absorb into the fibers of the polyester. Once cooled the pores in the fiber seal locking the dye in place. The image is permanent and unless bleached, the colors stay vibrant much longer. They are essentially permanent. Our photo-gifts such as mugs,tumblers, etc are produced using this method.

We are pleased to announce that after many hours with our vendors, we have learned how to give you vibrant sublimated prints on 100% cotton fabrics. No longer do the colors have to be white or light colors, or ever polyester. The prints last much longer and are vibrantly beautiful. Our cotton sublimated prints are placed on a specially made ultra thin vinyl surface that allows the dye inks to seal into the vinyl. They are then heat applied to the garment. It is not layered.

When using sublimation to produce your product I only use the manufactures' recommended process. I do not use any hacks, short cuts or cheaper brands. I believe in doing so reduces the quality of the your product. My promise to you is to provide you with the best quality possible. I intended to do that every step of the way.

Why Cotton over Polyester

Polyester is a synthetic man made fiber. Polyester is designed to be moisture wicking, wrinkle resistant, fade resistant, stain resistant. more durable, and stretchy than cotton. However, polyester does not breathe well and is not hypoallergenic. It is a heavier fabric than cotton. While it has great features we love the softness of cotton and believe you do too.

Cotton is a natural fiber grown by plants to product fabric products. It has been around for hundreds of years. It is lightweight and breathable. Cotton is hypoallergenic and does not hold odors like polyester. With our new training , cottons do work with all of our printing processes.

Polyester is a synthetic man made fiber. Polyester is designed to be moisture wicking, wrinkle resistant, fade resistant, stain resistant. more durable, and stretchy than cotton. However, polyester does not breathe well and is not hypoallergenic. It is a heavier fabric than cotton. While it has great features we love the softness of cotton and believe you do too.

Cotton is a natural fiber grown by plants to product fabric products. It has been around for hundreds of years. It is lightweight and breathable. Cotton is hypoallergenic and does not hold odors like polyester. With our new training , cottons do work with all of our printing processes.

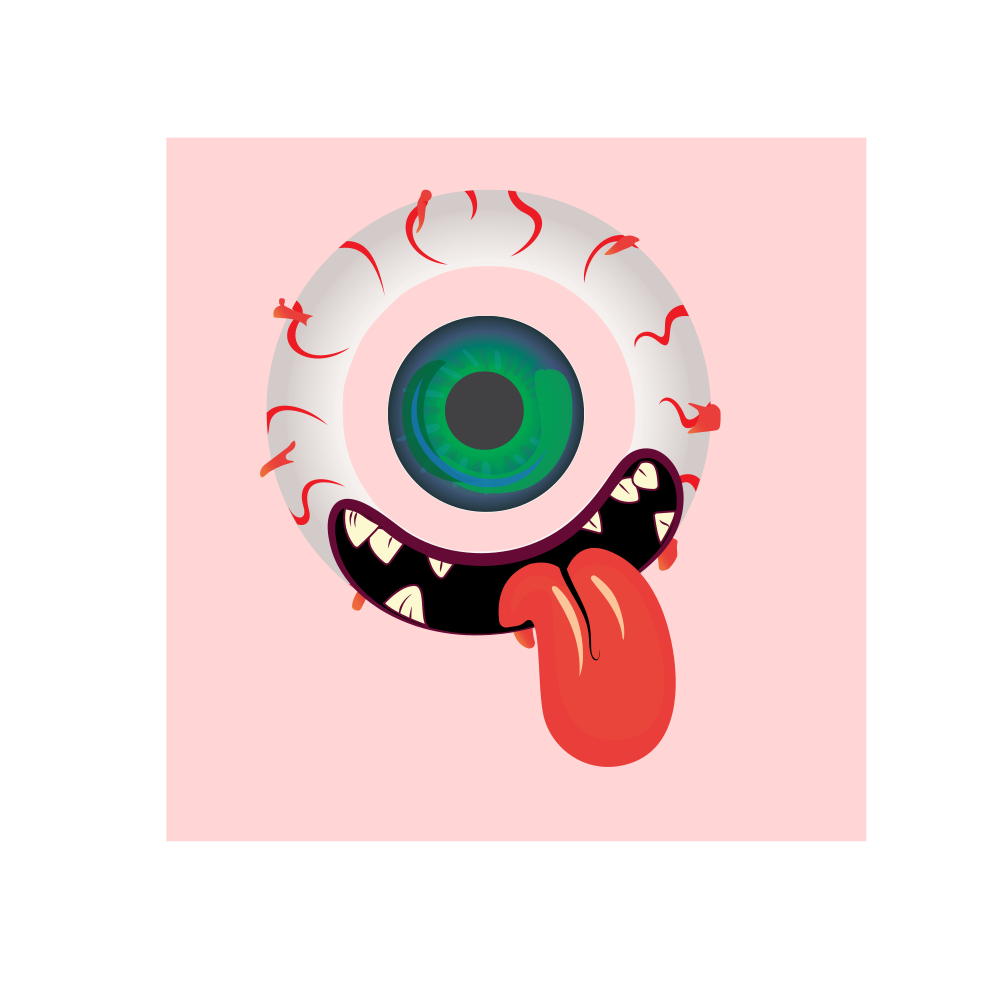

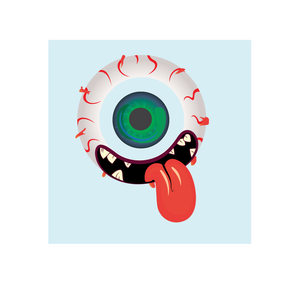

Why does sublimation only work on white backgrounds?

Sublimation Ink is a dye of four basic colors that when combined together make vivid and vibrant prints. Just like in any printer only CMYK (cyan, magenta, yellow, black) colors are used. These four colors can not be combined to make or print white. White areas of the print are left without dye. When the dye is transferred onto the specially coated polyester surface white areas stay white. For example if we used a light blue tee to sublimate a set of eyes, the white parts of the eyes would be light blue and not white. The reason for this is because the background is light blue. We only use specially designed and specialty coated products for our sublimation print. Notice what happens to the white around the Iris of this design. See how it changes color based on the background.

Sublimation Ink is a dye of four basic colors that when combined together make vivid and vibrant prints. Just like in any printer only CMYK (cyan, magenta, yellow, black) colors are used. These four colors can not be combined to make or print white. White areas of the print are left without dye. When the dye is transferred onto the specially coated polyester surface white areas stay white. For example if we used a light blue tee to sublimate a set of eyes, the white parts of the eyes would be light blue and not white. The reason for this is because the background is light blue. We only use specially designed and specialty coated products for our sublimation print. Notice what happens to the white around the Iris of this design. See how it changes color based on the background.

HTV (Heat Transfer Vinyl) Tees

We use HTV (Heat Transfer Vinyl) or Performance vinyl for our designs that are placed onto cotton. As stated previously, sublimation cannot be performed on cotton without using a polyester base. When a design requires sublimation, we use several different products to place the design onto the shirt. Holographic Pearl for shimmer, Glitter for extra sparkle and shine, and or EasySubli.

Using software and a plot cutter we can cut each vinyl piece to match the one before creating near perfect results over and over again. The color choices are endless and designs can be altered or changed at any time. Vinyl can be placed on just about any surface and substrate. Whether its a shirt, mug, hat, glass, wood, ceramic, etc. The vinyl will adhere giving you a vivid colored design for years to come. Vinyl can be either heat transferred, permanent and or removable for solid surfaces.

The vinyl used for apparel decoration is light weight, stretchable, vivid and of the best quality, They last for years to come even if washed and dryed on low heat, inside out to prevent damage. Since it is heat applied it can also be heat removed with extremely high temperatures above 400 degrees F. Meaning that a clothes dryer operating under normal conditions, as it is designed to operate, should not remove or damage the vinyl. A dryer under normal conditions should not operate higher that 170 degrees. When washing and drying your vinyl printed product, always wash inside out on low heat or hang to dry.

What is a Layered Design?

This process is used on vinyl printed designs that require it. A layered design is just what it says, one layer of vinyl on another. In some designs this can not be avoided. We work with our designs to avoid this whenever possible. The reason is that the more layers a design has the thicker and heavier it becomes. Since vinyl is heat applied, it lays on top of the fabric. We only layer a design when it is requested by a client. All multicolored designs are printed using the sublimation method.

What do you mean by cut and piece together?

When creating with HTV vinyl, designs are grouped together by colors and cut using a vinyl cutter or plotter. The design must then be placed and pressed individually. Here's an example using a black tee and a cute monkey design. (note: the black parts and outline are created by the tee)

Using software and a plot cutter we can cut each vinyl piece to match the one before creating near perfect results over and over again. The color choices are endless and designs can be altered or changed at any time. Vinyl can be placed on just about any surface and substrate. Whether its a shirt, mug, hat, glass, wood, ceramic, etc. The vinyl will adhere giving you a vivid colored design for years to come. Vinyl can be either heat transferred, permanent and or removable for solid surfaces.

The vinyl used for apparel decoration is light weight, stretchable, vivid and of the best quality, They last for years to come even if washed and dryed on low heat, inside out to prevent damage. Since it is heat applied it can also be heat removed with extremely high temperatures above 400 degrees F. Meaning that a clothes dryer operating under normal conditions, as it is designed to operate, should not remove or damage the vinyl. A dryer under normal conditions should not operate higher that 170 degrees. When washing and drying your vinyl printed product, always wash inside out on low heat or hang to dry.

What is a Layered Design?

This process is used on vinyl printed designs that require it. A layered design is just what it says, one layer of vinyl on another. In some designs this can not be avoided. We work with our designs to avoid this whenever possible. The reason is that the more layers a design has the thicker and heavier it becomes. Since vinyl is heat applied, it lays on top of the fabric. We only layer a design when it is requested by a client. All multicolored designs are printed using the sublimation method.

What do you mean by cut and piece together?

When creating with HTV vinyl, designs are grouped together by colors and cut using a vinyl cutter or plotter. The design must then be placed and pressed individually. Here's an example using a black tee and a cute monkey design. (note: the black parts and outline are created by the tee)

Here is the same design on a light blue tee. The process is the same except, that a piece of black is used as the base of the monkeys face. This makes it a layered design, but without it, the design would not look as cute.

The great thing about HTV vinyl is that the choices are really endless. You can change colors and even types of vinyl to create different effects. Here's a few examples

Who are our supply vendors?

CONDE

For our sublimated products we only use CONDE (now Dyetrans) for our sublimation needs. They are the leaders and innovators of the apparel decorating industry for over 30 years. They provide us with the best methods, technology, products and support to give you the best products possible.

SAWGRASS Technology

SAWGRASS Technology is the worlds' leader in software and dye inks. They are the original creators of sublimation inks and have maintained that status for over 25 years.

Alpha Broder

Alpha Broder is our choice for top quality apparel products. Alpha Broder has been the nations leader for over 20 years, with 10 distribution centers across the nation. Their partnerships give access to over 6500 different styles and 60 brands for you to choose from.

SISER HTV

SISER has been in the vinyl business for over 40 years. They hold true to their core values on honesty, integrity, high quality standards.

CAREGY HTV

Every once in a while you have to give the new guy a try and I am so glad I did. CAREGY HTV offers great HTV vinyls in vibrant colors and prints. Their products have always been top quality every time I have used them.

All of our vendors have built their organizations based on TRUST and INTEGRITY and have held true to that. They possess the same values we do.

For our sublimated products we only use CONDE (now Dyetrans) for our sublimation needs. They are the leaders and innovators of the apparel decorating industry for over 30 years. They provide us with the best methods, technology, products and support to give you the best products possible.

SAWGRASS Technology

SAWGRASS Technology is the worlds' leader in software and dye inks. They are the original creators of sublimation inks and have maintained that status for over 25 years.

Alpha Broder

Alpha Broder is our choice for top quality apparel products. Alpha Broder has been the nations leader for over 20 years, with 10 distribution centers across the nation. Their partnerships give access to over 6500 different styles and 60 brands for you to choose from.

SISER HTV

SISER has been in the vinyl business for over 40 years. They hold true to their core values on honesty, integrity, high quality standards.

CAREGY HTV

Every once in a while you have to give the new guy a try and I am so glad I did. CAREGY HTV offers great HTV vinyls in vibrant colors and prints. Their products have always been top quality every time I have used them.

All of our vendors have built their organizations based on TRUST and INTEGRITY and have held true to that. They possess the same values we do.